Wind Turbine Recycling

Wind Turbine Recycling

Efficiently cut windturbine blades with large blades and

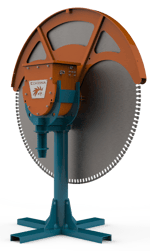

Echidna high-performance excavator saws

Background

As existing wind turbines approach their end of life, they must be reduced to small enough pieces that they can be transported to a disposal facility.

Wind-turbine blades are usually made from glass or carbon fibre in a polymer matrix. It is light, and tough material, and methods of demolition are limited.

Wind farms are often located in farmland, and it is essential that after cutting, the site is left free of debris.

Echidna excavator circular saws have proven to be an excellent tool for the cutting of wind-turbine blades on site.

Around Europe, wind farm installations where turbines are to be decommissioned, have benefited from the application knowledge and expertise of Echidna.

Advantages of Echidna Excavator Saws

The Echidna hydraulic circular saw solution offers these advantages over other techniques such as crushers:

- fast cutting, high productivity

- no debris left on site

- cutting can be done on freely resting blades at any angle with no need for positioning or clamping down

- even greater versatility can be achieved with the assistance of Echidna rotation heads, swivel heads and/or linear guide rails

- an excavator demolition saw takes little time to prepare; connect to an excavator via any quick hitch and start cutting

Excavator Saw Selection Criteria

Wind turbine blades have a complex structure to give them rigidity without too much weight.

Small blades can only cut through partial sections of the structure, which makes the blade become floppy but remain in one piece, and it is difficult to turn it over to cut from the other side to separate the parts.

For this reason, it is preferable to to use saws with large blades to go through all of the layers.

Saws from our HP series are the best choice for this application. They provide high performance with large blade diameters for fast cutting and minimal handling of the blade.

Diamond Tip Composition

Echidna has worked with specialist diamond tip manufacturers to formulate diamond tips optimised for cutting through the wind turbine blades. These provide optimum cutting speed and low wear.

Recommended Equipment

We recommend the larger blade diameter diamond rock saws for cutting through the full depth of the wind turbine blades.