FAQS

📞 02 9980 7779FAQS

Is 'no case drain' a good thing?

One of the features of many rocksaws is "no case drain required". But is that a good thing?

We could ask this question a different way.

would you want your

20 tonne excavator

to perform like a

10 tonne excavator?

Probably NOT!

What is the advantage of 'no case drain'?

Up-Front Cost

- Rock saws which do not require case drain are usually powered by orbital hydraulic motors. These are one of the cheapest kind of motors

- you don't need to install a case drain line on your excavator

What are the disadvantages?

- lower efficiency - slower cutting

- less versatile machine - there is a very limited range of excavators that the orbital motor can be safely used on

- low pressure capabilities -> not much torque so the blade stalls too easily

- low flow capabilities -> can't use smaller blades which are cheaper and reduce torque requirements

Lower Efficiency with no case drain

Orbital motors (no-case drain required) have fairly limited pressure and flow capabilities. This means that each model has a quite narrow range of excavators for which it suitable, and equally limited range of blade sizes for which it can operate efficiently.

They can be constructed in such a way that allows an internal connection of the case space to the oil return line, but this comes at the cost of significant loss of efficiency compared to other types of motors.

Connecting a case drain to the orbital motors

- allows about 10% increase in pressure between the oil in and oil out of the motor, which results in an increase in torque and efficiency.

- extends the working life of the motor. Both gains are a good thing.

Less versatile Machine

The low pressure and flow capabilities mean that to get the most out of your 'no-case drain' rocksaw, you need to select a motor size to suit your excavator. On another excavator, it may not work so well. Our standard range of rocksaws (D1S, D2S, D3S and D4S) have many motor sizes available so that we can find the best match with your excavator. Other companies just have a "one size fits all" policy, which doesn't give good results

Low Flow and Pressure Capabilities

This combination of low flow and low pressure is unfortunate.

Diamond cutting requires good tip speed. Speed of the saw (rpm) is directly related to the flow capabilities of the motor. To compensate for low speed, you must put on a bigger blade to get the tip speed high enough for efficient cutting.

To keep the blade spinning, you also require torque to overcome friction, and the torque needed increases with blade size. Limiting pressure means that you are also limiting torque.

Putting these two factors together, the blade range is constrained by both the pressure and flow limitations - and often there is no good blade to suit a given motor.

What is the alternative?

We use the "no case drain" motors in our standard models (D1S, D2S, D3S and D4S) as a cheaper alternative for the budget sensitive, but all our high performance (D3HP, D3HS, D4HP, D4HS, D5HP, D6HP) machines always require a case drain.

They are powered by piston motors which have quite a different construction to the orbital motors. They have higher efficiency, and they can operate at higher flows and pressures than the orbital motors, making each of them a much more useful piece of machinery. They can be used on a greater range of excavators without limiting either the pressure or flow, and they are substantially better in performance.

So while "no case drain" is more convenient, and a little cheaper at set up time, you are losing out on productivity in a very significant way.

Productivity equals money.

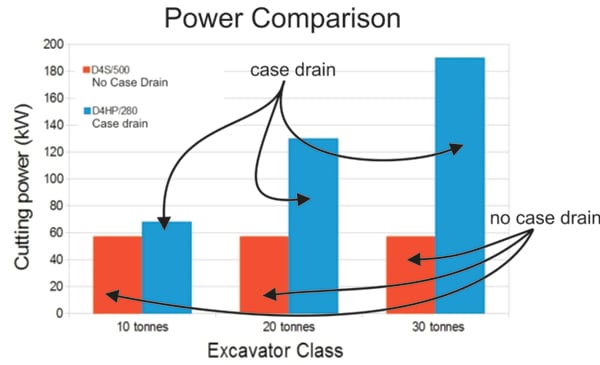

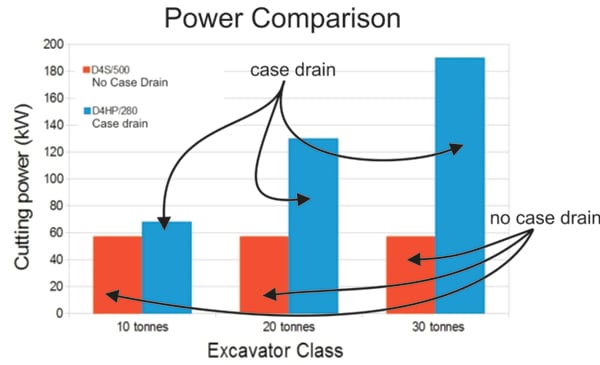

We compared the performance of our D4S/500 model (the precise equivalent of Groundtech's GTS3/500) with our D4HP/280

Comparison between D4S/500 Rocksaw (no case drain) and D4HP/280 Rocksaw (case drain)

For comparison, we can compare the D4S/500 from our standard range with the D4HP from the High Power range cutting sandstone.

The D4S does not require a case drain line, the D4HP does.

| D4S/500 | D4HP/280 |

|---|---|

|

|

10 tonne excavator - 51kW *

| Machine | Cutting Power |

|---|---|

| D4S/500 | 57 hp (42.5kW) |

| D4HP/280 | 68 hp(51kW) |

20 tonne excavator - 96kW **

| Machine | Cutting Power |

|---|---|

| D4S/500 | 57 hp (42.5kW) |

| D4HP/280 | 130 hp (96kW) |

30 tonne excavator - 141kW ***

| Machine | Cutting Power |

|---|---|

| D4S/500 | 57 hp (42.5kW) |

| D4HP/280 | 190 hp (141kW) |

For the calculations, the following parameters have been used for the excavators

*10 tonne : flow 125 l/min, pressure 20MPa, Power 51kW

**20 tonne : flow 215 l/min, pressure 25MPa, Power 96kW

***30 tonne : flow 295 l/min, pressure 25MPa, Power 141kW

Blade Size Comparison

We can also compare the blade size range for the D4S/500 and the D4HP/280

| excavator /tonnes | Blade Diameter | |||

| D4S/500 | D4HP/280 | |||

| Min. | Max | Min. | Max | |

| 10 | - | - | 1400 | 1800 |

| 20 | 1800 | 2000 | 800 | 2000 |

| 30 | 1800 | 2000 | 600 | 2000 |

The D4S/500, which is exactly the same as, for example Groundtech GTS3, is on the one hand limited to large blades, bacause smaller blades do not have sufficient tip speed to be efficient Read more about tip speed

On the other hand, because the working pressure range is limited to 200 bars, they do not work all that well even with the large blades in comparison with high efficiency piston motors.

This means that for concrete cutting (which usually requires only a shallow cut, i.e. small blades) it is not economical, and it is not at all suited to other applications such as stump grinding and wood cutting.