All Rock & Concrete Saws for Robots and Excavators

All Rock & Concrete Saws for Robots and Excavators

Excavator Saws have a wide application in

- earthmoving and excavation for construction

- demolition

- trenches for telecommunications, plumbing, pipelines

- recycling

- forestry

Applications

They allow for precision cutting through a variety of materials.

Excavator saws produce a neat cut, with minimal damage and destruction. Apart from being a highly efficient method of material removal, they can also assist with reducing the need for other materials such as concrete in footings.

Excavator saws are

- safer

- quieter

- less destructive

than other methods of rock and concrete removal.

Types of Excavator Rocksaw

Echidna designs and builds three types of excavator saws, each with their advantages for particular applications.

Very briefly,

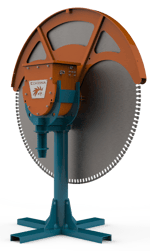

Diamond Rocksaws

- Excavator diamond rocksaws are the most versatile choice

- Cut the widest variety of materials including metals, fibreglass, wood

- Cut medium to hard rock and reinforced concrete. Replace the blade to cut metals, wood and plastic

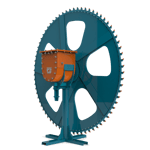

OmniCut® Rocksaws

- Powerful, fast cutting OmniCut(R) Rocksaws

- Developed by Echidna to maximise your excavator's cutting potential

- OmniCut(R) rocksaws can provide the most cost effective cutting.

- Available in small and large blade models, with variable blade width for trenching

Tungsten-Carbide Rocksaws

- The most robust technology for excavator rocksawing, for materials such as soft stone and lightly reinforced concrete

- Easy onsite tip replacement and no need for cooling water gives tungsten-carbide an advantage in quarries and remote locations

- Low tip speed means greater safety on-site than with fast spinning blades

How do I select the Right Type of Rocksaw?

Echidna produces such a wide range of excavator saws, it is not always easy to choose.

Use our online to help to narrow the options with regards to the type of cutting technology which should be used for a particular application.

Check the specifications of the selected rocksaw.

While the above points provide rough guidance, there are many considerations to be taken into account.

| Tungsten Carbide | Diamond | Omnicut |

Cooling water not required | ✔ | X | ✔ |

Cut |

|

|

|

concrete* | ✔* | ✔ | ✔ |

bitumen/asphalt | ✔ | ✔ | ✔ |

hard rock >80MPa | X | ✔ | ✔ |

|

soft rock <50MPa |

✔ |

X |

✔** |

|

other materials (metals, carpet, fibreglass, wood ....) |

✔ |

X |

✔ |

Wide Cut |

✔ |

X |

✔ |

Light weight |

X |

X |

X |

Suitable for excavators |

|

|

|

|

large (15 - 70 tonne) |

✔ |

✔ |

✔ |

|

medium (8-15 tonne) |

✔ |

✔ |

✔ |

|

small (1-8 tonne) |

X |

✔ |

X |

High tip speed(versatility, small blades) |

X |

✔ |

X |

Low tip speed(increased safety) |

✔ |

X |

✔ |

Very low vibration |

X |

✔ |

✔ |

Low vibration(compared with alternatives to rock saws) |

✔ |

✔ |

✔ |

On-site tip replacement |

✔ |

X |

✔ |

Very low maintenance |

✔ |

✔ |

X |

High productivity in medium to hard rock |

X |

✔ |

✔ |

* lightly reinforced concrete can be cut with tungsten-carbide rocksaws

** soft abrasive stone increased wear of holders